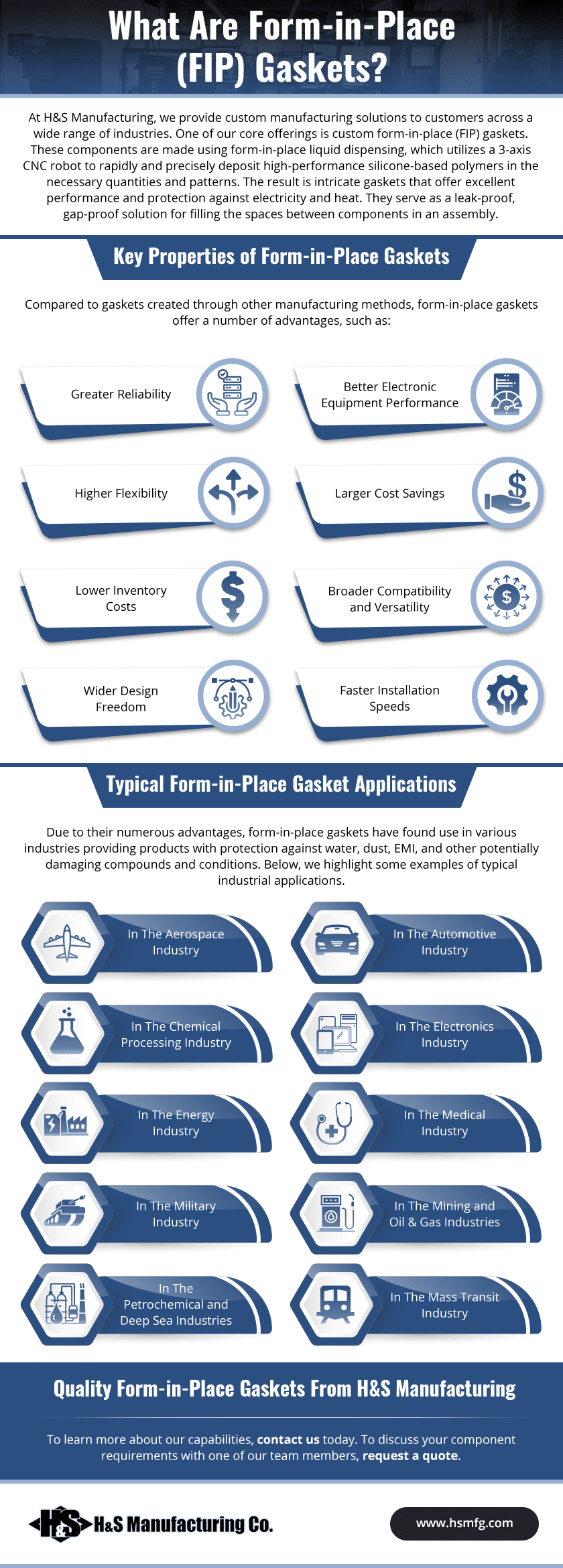

What Are Form-in-Place (FIP) Gaskets?

At H&S Manufacturing, we provide custom manufacturing solutions to customers across a wide range of industries. One of our core offerings is custom form-in-place (FIP) gaskets. These components are made using form-in-place liquid dispensing, which utilizes a 3-axis CNC robot to rapidly and precisely deposit high-performance silicone-based polymers in the necessary quantities and patterns. The result is intricate gaskets that offer excellent performance and protection against electricity and heat. They serve as a leak-proof, gap-proof solution for filling the spaces between components in an assembly.

Key Properties of Form-in-Place Gaskets

Compared to gaskets created through other manufacturing methods, form-in-place gaskets offer a number of advantages, such as:

- Greater reliability. Form-in-place gaskets provide more reliable protection for compartmentalized enclosures and packaged electronic assemblies.

- Better electronic equipment performance. Form-in-place gaskets can be used for EMI protection in electronic devices and systems, where they help ensure uninterrupted equipment performance.

- Higher flexibility. Form-in-place gaskets are highly flexible, which enables them to flex in response to flange movements. As a result, they are less likely to fail in dynamic applications.

- Larger cost savings. Form-in-place gaskets require less raw material and labor to make than other types of gaskets, which translates to lower production costs.

- Lower inventory costs. Since form-in-place gaskets can be manufactured when they are needed, companies do not have to keep a stock of gaskets in a variety of shapes and sizes, which helps reduce their inventory costs.

- Broader compatibility and versatility. Form-in-place gaskets can adhere to a range of metal, plastic, and plated substrates, which enables them to be used in many different applications.

- Wider design freedom. Form-in-place gaskets can be made in large or small sizes and simple or intricate shapes to suit their intended applications.

- Faster installation speeds. Form-in-place gaskets are ready to use once they are dispensed, which allows them to be installed much faster than gaskets produced by other methods.

Typical Form-in-Place Gasket Applications

Due to their numerous advantages, form-in-place gaskets have found use in various industries providing products with protection against water, dust, EMI, and other potentially damaging compounds and conditions. Below, we highlight some examples of typical industrial applications.

- In the aerospace industry: aircraft seats, drones, flight instruments, ground support equipment

- In the automotive industry: air and oil filters, doors and windows, external engine parts

- In the chemical processing industry: processing equipment and systems

- In the electronics industry: communication systems, electronic enclosures, semiconductors

- In the energy industry: generators, transformers, alternative energy systems (e.g., solar panels)

- In the medical industry: medical devices, such as dialysis machines, heart pumps, oxygenators, and ventilators

- In the military industry: global positioning systems (GPS), missile guidance systems, radar systems

- In the mining and oil & gas industries: communication systems, power generators, processing equipment, vehicles

- In the petrochemical and deep sea industries: devices and systems that require leak-proof seals

- In the mass transit industry: mechanical systems, seating, windows, and doors

Quality Form-in-Place Gaskets From H&S Manufacturing

Form-in-place gaskets are a key component of many industrial and consumer products. Since they are made using robotic liquid dispensers, they can be formed quickly without sacrificing quality, which saves users time and money.

If you need form-in-place gaskets, H&S Manufacturing is the ideal partner. We manufacture durable EMI shielding components that are compatible with metal, plastic, and plated substrates. To learn more about our capabilities, contact us today. To discuss your component requirements with one of our team members, request a quote.

Email Us

Email Us

Comments are closed